SHELL AND TUBE & EVAPORATIVE CONDENSERS

SHELL AND TUBE & EVAPORATIVE CONDENSERS

Rano Tech Co., Ltd.

is Thermal Engineering Company who specialist in all kind of Heat Exchangers , Cooler , Heater. Both single phase and two phases. We are using world-class softwares and engineering to make our final equipment meet world class standard and quality. With our 22 years experience in the field. We proud to be a part of your success story. With our compromised cost and excellent services, our products will be competitive in most dimensions. Our raw material will be imported from worldclass sources, or local by the premium quality suppliers. We also supply Evaporative Condensers for Ammonia (refrigeration system) from the most superior manufacture เรามี อีแว๊ปโปเรทีฟ คอนเดนเซอร์ สำหรับงาน แอมโมเนีย (ใช้ใน ระบบทำความเย็น) จากโรงงานมาตฐานโลก ประกอบ เชื่อมด้วยหุ่นยนต์ Robotic Welder and Assembly. Heat Pump is another our proud products. Our Heat pump / Chiller are supply with high COP (coefficient of performance). Catalog and datasheet can supply upon your requested in our inquiry form. Plate Heat Exchanger (PHE) is the highest efficiency among all kind of heat exchangers. For some clear Liquid/Gas application PHE will be the first choice. We also can offer Thermal Design to meet with your application. We have Engineering Team who are ready to support your activities. Our PHE material stocked are AISI316 , Titanium . Gasket type , Copper Brazed Type, Nickel Brazed Type. Most of generally usage range are in our Stock which prompt delivery within 2-3 days.

Rano Tech Co., Ltd.

ขั้นตอนการออกแบบ ผลิต Shell and Tube , Air Cooler

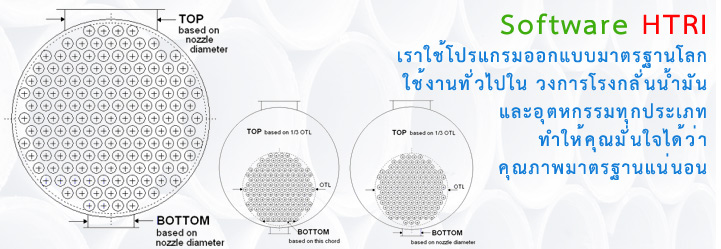

Thermal Design โดยใช้ software ของ ASPEN, HTRI (www.HTRI.net) ซึ่งเป็น โปรแกรมออกแบบมาตรฐานโลก ใช้งานทั่วไปใน วงการโรงกลั่นน้ำมัน , offshore , petroleum , petrochemical, chemical , foods , heavy industry, paper mill. Mechanical Design , Finite Element Analysis โดยใช้ software COMPRESS (ASME code) (www.codeware.com) ผลิต โดย workshop มาตรฐานโลก จาก Our Local Workshop

ผลิตตามมาตรฐาน ราคาเหมาะสม

Transalindo Batam & Heat Transfer Solutions Indonesia

some project experiences such-as:

- Natural Gas Booster Station, PT Agip Lubrindo Pratama.

- Revamping project, Octanol/ N-Butanol/ I-Butanol Industry, PT Petro Oxo Nusantara.

- Onshore Oil Treating and LPG Recovery Facilities Plant, Hess Indonesia Pangkah Ltd.

- Wunut Gas Compressor Re-Staging Cooler, Lapindo Brantas Inc.

- Singa Gas Development Project, Lematang South Sumatra, PT. Medco E&P Indonesia

- Jambi Merang Development Gas Production Facilities, JOB Pertamina Talisman

- PPP Compressor Discharge Cooler Project, KODECO.

BBI www.ptbbi.co.id

- Japan, Sun Arrow Project – Pressure Vessels

- Malaysia, Enco System Project – Membrane Walls for Boiler

- Malaysia, MNI Project – Condensers & Heaters

- Mexico, La Paloma Project – Condensers & AD Vessels

- Mexico, Monterey Project – Condensers

- Mexico, Rosarito Project – Condensers & AD Vessels

- Myanmar, KHI A / B Project – CB Condensers

- Philippine, Mahanaglong Project – Gland Steam Condensers

- Singapore, Tuas Power Plant – Condensers

- South Korea, Poryong Project – CCW Cooler

- Taiwan, Formosa Project – LP Heaters

- USSR, PTA Project – Gland Steam Condensers

- Australia, Pelican Point Project – Condensers, Deaerators & Pressure Vessels

- China, Yoe Yang Power Project – Water Box

- Egypt, Assuit Power Plant – Condensers